La serie U3700 es un sensor IMU/VRU/AHRS compuesto por una matriz MEMS-IMU y un magnetómetro. Está equipado con un filtro Kalman adaptativo extendido de desarrollo propio, un algoritmo de análisis dinámico de ruido de la IMU y un algoritmo de análisis del estado del movimiento de la portadora, lo que garantiza la precisión del ángulo de actitud en condiciones altamente dinámicas y reduce la deriva del ángulo de rumbo.

Cada sensor se somete a una compensación fina que incluye temperatura, polarización cero, factor de escala y eje transversal antes de salir de fábrica.

Los sensores de la serie U3700 transmiten datos a través de diversas interfaces, como UART (RS-232/TTL), RS-485 y CAN, y ofrecen amplias configuraciones de usuario. La serie U3700 puede sincronizarse con el sistema mediante disparo externo y también con sistemas externos, como radares y cámaras, mediante la función de salida síncrona. Su interfaz gráfica de usuario (GUI) multifuncional facilita la evaluación rápida de los productos, incluyendo, entre otras funciones, la configuración de módulos, la visualización de datos, la actualización de firmware, el registro de datos, etc.

Número de pieza, :

U3700Pedido (MOQ) :

11. Especificación del producto

|

Parámetro |

U3700-A |

U3700-B |

U3700-C |

U3700-D |

Unidad |

|||||||

|

Actitud Precisión |

||||||||||||

|

Paso (±90°) /Rollo (±180°) (estático) |

0,15 (normal), 0,2 (máximo) |

° |

||||||||||

|

Paso (±90°) /Rollo (±180°) (dinámica) |

0,15 (normal) 0,3 (máximo) |

0,15(normal) 0,2 (máximo) |

° |

|||||||||

|

Guiñada (±180°) deriva estática 2 horas (6 grados de libertad) ① |

0,15 (normal), 0,2 (máximo) |

°

|

||||||||||

|

Guiñada (±180°) deriva dinámica (6DOF) ② |

9

|

5 |

5 |

5 |

° |

|||||||

|

Masistencia magnética (AHRS)③ |

2(normal), 3(máximo) |

° |

||||||||||

|

Error de rotación de guiñada (6DOF) (rotación bajo 100°/s)④ |

3(máximo) |

<0,8 (normal) 1,3 (máximo) |

<0,8 (normal) 1,3 (máximo) |

1(máximo) |

° |

|||||||

|

Resolución |

0.01 |

° |

||||||||||

|

Nota: ① Módulo estacionario horizontalmente durante 2 horas. ② El módulo se midió después de 1 hora de movimiento en un robot de interior.,1σ ③ Después de la calibración geomagnética, el producto debe configurarse en modo AHRS cuando no haya interferencia de campo magnético en el área circundante. ④ El plato giratorio gira continuamente durante 10 vueltas y el ángulo de rumbo acumula errores.. |

||||||||||||

|

Giroscopio de 3 ejes |

U3700-A |

U3700-B |

U3700-C |

U3700-D |

Unidad |

|||||||

|

Mrango de medición |

±2000 (ajustable) |

°/s |

||||||||||

|

Resolución |

16 |

poco |

||||||||||

|

Factor de escala(100°/s)① |

<600(normal) 800(máximo) |

<280 (normal) 350 (máximo) |

<280 (normal) 350 (máximo) |

<280 (normal) 300(máximo) |

ppm |

|||||||

|

Nonlinearidad② |

±0.05 |

%Fs |

||||||||||

|

Ancho de banda de 3dB |

47(normal) – 230 (máximo) |

Hz |

||||||||||

|

Muestreo |

1000 |

Hz |

||||||||||

|

Cero sesgo enestabilidad (Alano)③ |

5.1 |

2.5 |

2.5 |

1.76 |

°/h |

|||||||

|

Sesgo cero repetibilidad (Alano)③ |

0.09 |

0.05 |

0.05 |

0.03 |

°/s |

|||||||

|

Paseo aleatorio angular (Allan)③ |

0.6 |

0.3 |

0.3 |

0,21 |

°/√h |

|||||||

|

Temperatura completa con polarización cero: 40-85℃④ |

Z: 0,015 (normal) – 0,035 (máximo) Y: 0,05 (normal) – 0,018 (máximo) X: 0,03 (normal) – 0,08 (máximo) |

°/s |

||||||||||

|

Sensibilidad del acelerómetro (los tres ejes) |

0.1 |

°/s/g |

||||||||||

|

Notas: ①:Gire el plato giratorio 10 veces en ambas direcciones y tome la medida promedio ②:Desviación máxima de la línea de mejor ajuste dentro del rango especificado ③: Consulte la 5.1 ~ 5.3 -Curva de varianza de Alan ④:La pendiente de aumento de temperatura medida por el plato giratorio de la cámara de temperatura en el laboratorio es menor a 3℃/min. Para obtener datos detallados, consulte la Figura 13 para la curva de compensación de temperatura. |

|

|||||||||||

|

Acelerómetro de 3 ejes |

U3700-A |

U3700-B |

U3700-C |

U3700-D |

Unidad |

|||||||

|

Mrango de medición |

±12 (ajustable) |

g |

||||||||||

|

Resolución |

16 |

poco |

||||||||||

|

Deriva de sesgo inicial① |

5(máximo) |

mg |

||||||||||

|

Nonlinearidad |

0,5 (normal) |

%Fs |

||||||||||

|

Ancho de banda de 3dB |

145 |

Hz |

||||||||||

|

Muestreo |

1600 |

Hz |

||||||||||

|

Cero sesgo enestabilidad (Alano)② |

0.06 |

0.03 |

0.03 |

0.021 |

mg |

|||||||

|

Sesgo cero repetibilidad (Alano)② |

2.52 |

1.5 |

1.5 |

0.6 |

mg |

|||||||

|

Paseo aleatorio angular (Allan)② |

0.08 |

0.04 |

0.04 |

0.028 |

EM/√h |

|||||||

|

Temperatura completa con polarización cero: 40-85℃③ |

1(normal) – 2,5 (máximo) |

mg |

||||||||||

|

Notas ①:Después de la instalación por parte del usuario, este valor puede cambiar según las condiciones reales; consulte 7.8 para conocer el sesgo cero inicial. ②: Consulte la 5.1~5.3 Curva de varianza de Alan ③:La pendiente de aumento de temperatura medida por el plato giratorio de la cámara de temperatura en el laboratorio es menor a 3 ℃/min. Para obtener datos detallados, consulte la Figura 13 para la curva de compensación de temperatura. |

||||||||||||

|

Magnetómetro |

U3700-A |

U3700-B |

U3700-C |

U3700-D |

Unidad |

|||||||

|

Rango |

±8 |

Gauss |

||||||||||

|

Resolución (Fs=2G) |

2 |

mGuass |

||||||||||

|

Muestreo |

200 (normal) |

Hz |

||||||||||

|

Linealidad (Línea recta de mejor ajuste Fs=2G) |

0,1 (normal) |

Fs% |

||||||||||

|

Sensor de temperatura |

U3700-A |

U3700-B |

U3700-C |

U3700-D |

Unidad |

|||||||

|

Rango |

-104(mín) – 150 (máximo) |

℃ |

||||||||||

|

Error de desplazamiento |

±1 |

K |

||||||||||

|

Mecánico/Ambiente |

U3700-A |

U3700-B |

U3700-C |

U3700-D |

Unidad |

|||||||

|

Fuente de alimentación |

7 - 48 |

V |

||||||||||

|

Consumo de energía |

300 |

400 |

400 |

600 |

mW |

|||||||

|

Temperatura de trabajo |

-40 - +85 |

℃ |

||||||||||

|

Alcance del giroscopio |

±125 (minutos) –±2000 (normal/máximo) |

°/s |

||||||||||

|

Alcance del acelerómetro |

±3 (min) –±12(normal) –±24(máximo) |

g |

||||||||||

|

Hora de inicio① |

2 |

s |

||||||||||

|

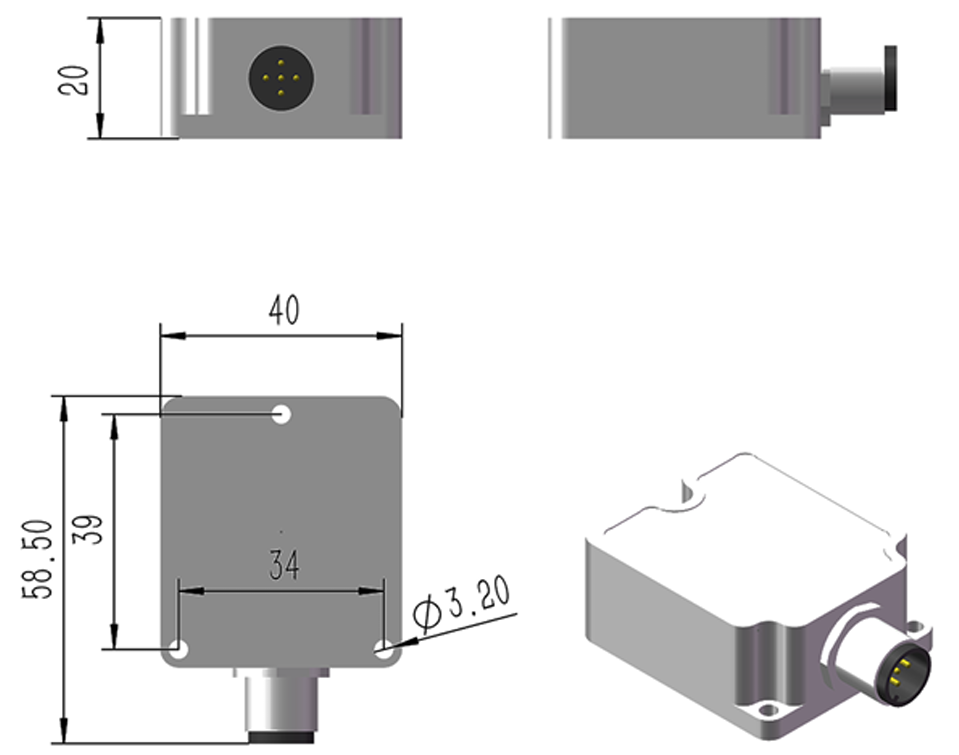

Tamaño |

Interfaz del conector M12: 58,5 x 40 x 20 Interfaz del conector PG: 40*36*16 |

mm |

||||||||||

|

Peso |

<75 |

g |

||||||||||

|

Material y proceso de la carcasa |

CNC de aleación de aluminio |

|

||||||||||

|

Tornillos de montaje |

M3 |

|

||||||||||

|

Antivibración |

1,0 mm (10 Hz-58 Hz) y≤20 g (58 Hz-600 Hz) |

|

||||||||||

|

Choque (duración <1 ms) |

2000 |

g |

||||||||||

|

Protección del medio ambiente |

Directiva RoHS 2011/65/UE |

|

||||||||||

|

Compatibilidad electromagnética |

Directiva LVD 2014/35/UE |

|

||||||||||

|

Droprueba p |

Caída libre 3 veces en una plataforma experimental de 75 cm de altura |

|

||||||||||

|

Choque de temperatura |

Aumentar la temperatura de -40 a 85 ℃ en 1h, 5 veces |

|

||||||||||

|

Notas: ① El tiempo de arranque se refiere al tiempo que tarda el sistema en apagarse y generar datos válidos. Durante este período, el módulo debe permanecer inmóvil. |

||||||||||||

|

Interfaz |

Mínimo |

Normal |

Máximo |

Unidad |

||||||||

|

UART |

Tasa de baudios① |

9600 |

115200 |

921600 |

puntos básicos |

|||||||

|

Sposición de inicio |

0 |

1 |

|

poco |

||||||||

|

Longitud de los datos |

0 |

8 |

|

bits |

||||||||

|

Bit de parada |

|

1 |

|

poco |

||||||||

|

Suma de comprobación |

|

Ninguno |

|

poco |

||||||||

|

Velocidad de cuadros de salida② |

0 |

100 |

1000 |

Hz |

||||||||

|

Impedancia de entrada Impedancia de salida (232 rupias) |

3 300 |

5 10 millones |

7 |

kΩ Ω |

||||||||

|

PODER |

Tasa de baudios③ |

125 |

500 |

1000 |

kbps |

|||||||

|

Velocidad de cuadros de salida④ |

5 |

100 |

200 |

Hz |

||||||||

|

Impedancia de entrada⑤ (con120 resistencia Ω) (sin120 resistencia Ω) |

19 |

120

30 |

52 |

Ω

kΩ

|

||||||||

|

RS485 |

Velocidad en baudios (Modbus) (no Modbus) |

9600 9600 |

115200 115200 |

115200 921600 |

puntos básicos |

|||||||

|

Sposición de inicio |

0 |

1 |

|

poco |

||||||||

|

Longitud de los datos |

0 |

8 |

|

bits |

||||||||

|

Bit de parada |

|

1 |

|

poco |

||||||||

|

Suma de comprobación |

|

Ninguno |

|

poco |

||||||||

|

Velocidad de cuadros de salida (Modbus) (no Modbus) |

0 0 |

10 100 |

50 250 |

Hz |

||||||||

|

Impedancia de entrada⑤ (con120 resistencia Ω) (sin120 resistencia Ω) |

48 |

120 |

|

Ω

kΩ

|

||||||||

|

Desencadenar Alfiler |

Voltaje lógico alto Bajo |

2.0 |

|

0.6 |

V |

|||||||

|

Demora (Desde la activación hasta la transmisión de datos)⑥ |

|

|

800 |

us |

||||||||

|

Notas: ① Si se requieren modificaciones, consulte el manual de instrucciones y programación. ② El sensor admite salida de datos a 1, 5, 10, 50, 200, 250, 500 y 1000 Hz. ③Si se requieren modificaciones, consulte el manual de instrucciones y programación. ④El sensor admite salida de datos de 5, 10, 50, 100 y 200 Hz. ⑤De forma predeterminada, no hay ninguna resistencia de 120 Ω conectada ⑥Consulte el capítulo de la función de sincronización y el manual de instrucciones y programación para obtener información sobre la sincronización y configuración de la activación. |

||||||||||||

|

Ambiente |

||||||||||||

|

Temperatura de trabajo |

-40 ~ +80 |

℃ |

||||||||||

|

Temperatura de almacenamiento |

-40 ~ +95 |

℃ |

||||||||||

|

Antivibración |

1,0 mm (10 Hz-58 Hz) y≤20 g (58 Hz-600 Hz) |

|

||||||||||

|

Choque (duración <1 ms) |

2000 |

g |

||||||||||

2. Dimensión del producto

Xml política de privacidad blog Mapa del sitio

Derechos de autor

@ Micro-Magic Inc Reservados todos los derechos.

RED SOPORTADA

RED SOPORTADA