Power supply ripple, or simply ripple, is the periodic fluctuation of voltage or current in a power supply. This fluctuation poses a potential threat to the stable operation of electrical equipment. Excessive power supply ripple can reduce the power system's conversion efficiency, increase heat generation, and in severe cases, lead to system instability or even chip damage. Therefore, when designing a BUCK circuit, measures need to be taken to reduce power supply ripple to ensure system stability.

The following are some common methods for reducing BUCK power supply ripple:

According to the formula for switching power supplies, the magnitude of current fluctuation within the inductor is inversely proportional to the inductance value, and the output ripple is inversely proportional to the output capacitance value. Therefore, increasing the inductance and output capacitance values can reduce ripple.

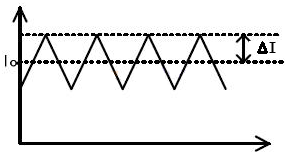

Figure 1 Inductor current

Figure 1 above shows the current waveform within the inductor L of a switching power supply. The ripple current ΔI can be calculated using the following formula. Based on volt-second balance and other parameters, it can be seen that increasing the inductor L value or increasing the switching frequency can reduce the current fluctuation within the inductor. Similarly, the relationship between output ripple and output capacitance is: Vripple = Imax/(Co × fsw). It can be seen that increasing the output capacitance value can reduce ripple.

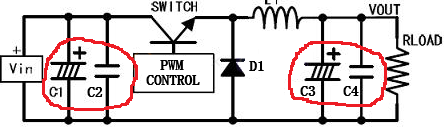

Commonly, aluminum electrolytic capacitors are used for the output capacitor to achieve a large capacitance. However, electrolytic capacitors are not very effective at suppressing high-frequency noise, and their ESR is relatively high. Therefore, a ceramic capacitor is connected in parallel next to it to compensate for the shortcomings of aluminum electrolytic capacitors.

When a switching power supply is operating, the input voltage Vin remains constant, but the current changes with the switch. When the power supply starts up or the load changes abruptly, an input capacitor is needed as a temporary energy pool to compensate for the instantaneous drop in input voltage. Typically, a capacitor is connected in parallel near the current input terminal (near the switch in a Buck type) to provide current. The input capacitor also suppresses ripple and electromagnetic interference (EMI) from the preceding power supply.

After adopting the above solution, the BUCK-type switching power supply is shown in the figure below:

Figure 2 BUCK topology

Figure 2 BUCK topology

The above approach has limited effect on reducing ripple. Due to size limitations, the inductor cannot be made very large; increasing the output capacitor to a certain extent has no significant effect on reducing ripple; and increasing the switching frequency will increase switching losses.

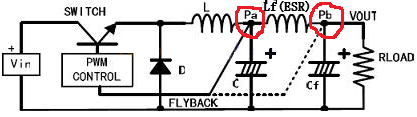

LC filters are effective at suppressing noise and ripple. By selecting appropriate inductors and capacitors to construct the filter circuit based on the ripple frequency to be removed, ripple can generally be reduced significantly. However, in this case, the sampling point of the feedback comparison voltage needs to be considered.

Figure 3

Figure 3

Selecting the sampling point before the LC filter (Pa) will result in a decrease in output voltage. This is because any inductor has a DC resistance, and when current is output, a voltage drop occurs across the inductor, causing the power supply's output voltage to decrease. Furthermore, this voltage drop varies with the output current. Selecting the sampling point after the LC filter (Pb) will produce the desired output voltage. However, this introduces an inductor and a capacitor into the power supply system, potentially affecting loop stability.

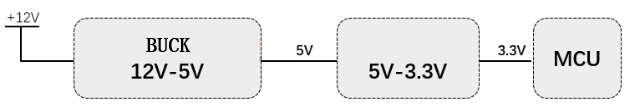

The most commonly used combination is BUCK+LDO, which is the most effective way to reduce ripple and noise. It provides a constant output voltage without requiring changes to the original feedback system, but this also reduces the overall power supply system efficiency and is the most expensive. A key metric for LDOs is PSRR (Power Supply Rejection Ratio), which quantifies the extent to which changes at the power input are transmitted to the output. After passing through an LDO, switching ripple is typically below 10mV.

The PCB layout of a switching power supply is also crucial for reducing ripple. Improper component placement, unreasonable grounding, or critical traces being close to the switch-sensitive area can cause increased ripple and high-frequency noise.

Xml política de privacidad blog Mapa del sitio

Derechos de autor

@ Micro-Magic Inc Reservados todos los derechos.

RED SOPORTADA

RED SOPORTADA